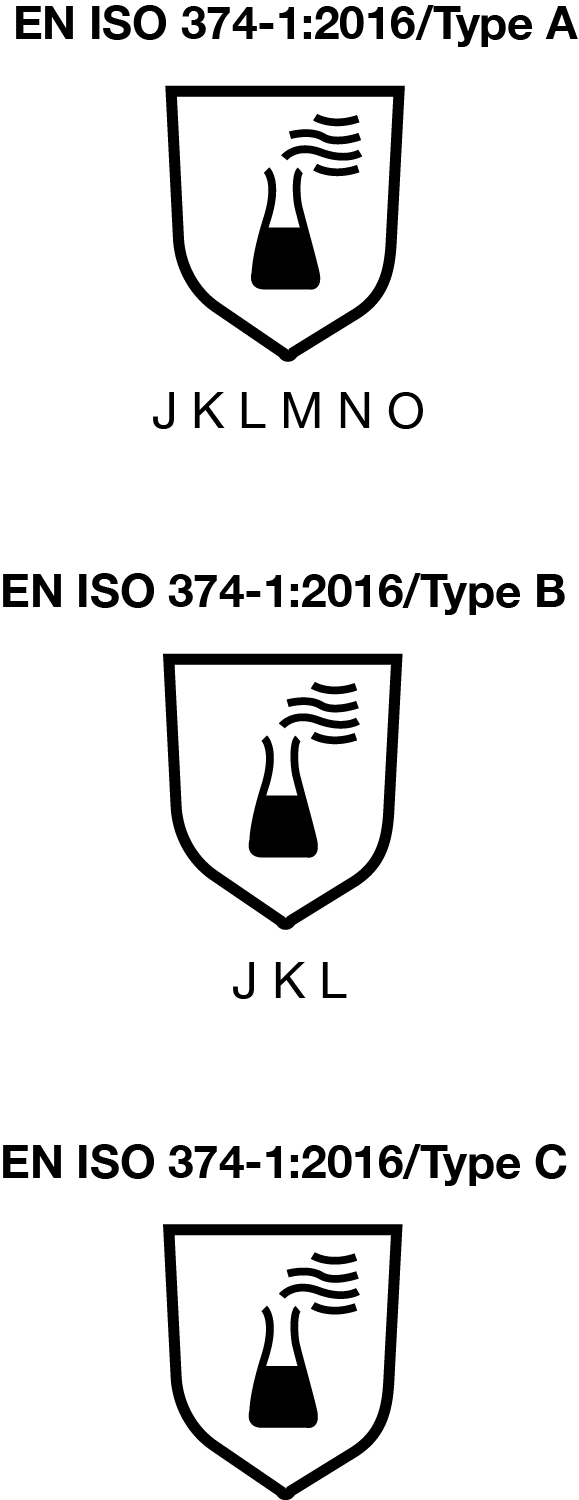

Type A: A chemical protective glove of this type prevents chemical permeation of at least 6 of the test chemicals for at least 30 minutes at a time.

Type B: A chemical protective glove of this type prevents the penetration of at least 3 of the test chemicals for at least 30 minutes.

Type C: A chemical protective glove of this type prevents chemical breakthrough (permeation) for at least 10 minutes for at least one of the test chemicals. (Previously, disposable gloves of this category were marked with a beaker).

The first part of the standard (EN 374-1) defines the performance requirements for chemical protective gloves, i.e. the extent to which they should protect against chemicals. Until now, the protection of a glove against chemicals could be declared with two different pictograms according to the European Standard 374. Another pictogram was used to certify that a glove protects against microorganisms such as bacteria and fungi.